“I tried being reasonable. I didn’t like it.”

Buy the Microtech Halo VI at BladeHQ

I always enjoyed that quote from Clint Eastwood, and couldn’t help but think about it as I wielded the Halo VI. There is absolutely nothing reasonable about this knife. Any justification that this would be my “new EDC” went completely out the window when I fired it for the first time and ~5″ of steel slammed out of the front with a terrific bang. Even more ridiculous is using the charging handle to recapture the blade. It’s something you would expect to see in a video game. This is a serious piece of hardware. It’s unlike anything I’ve ever owned before, and it revels in its unreasonableness.

But that’s part of what makes knife collecting fun. If everything was a Delica 4 there would be no point to it. Sure we would all have a practical knife clipped to our pocket, but the fun in collecting would be long gone. Thankfully we don’t need to worry about being confined to using a government knife to cut our government cheese any time soon. Unreasonable knives like the Halo VI are doing their part to keep the joy of collecting safely intact.

General Dimensions and Blade Details

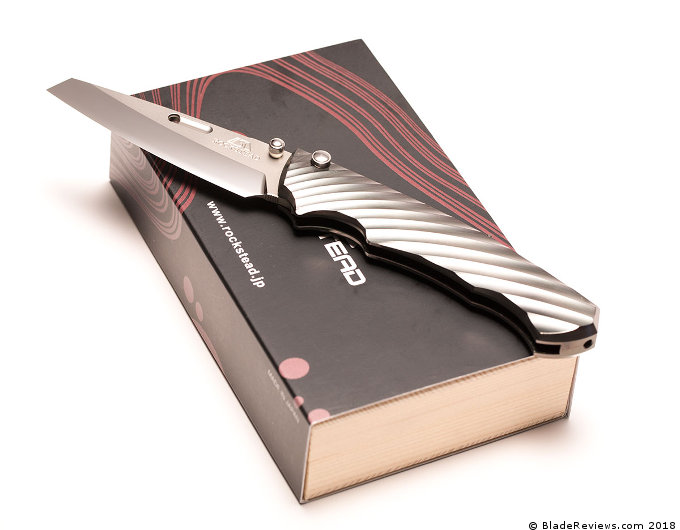

The Halo VI has an overall length of 10.82″, a 4.5″ blade, weighs 6.5 ounces, and is made in the USA. It’s the closet thing I’ll come to owning a light saber. It’s big, it’s unwieldy. If comes from a long series of Halo knives. I won’t proclaim to be an expert on all things Microtech, but my understanding is that this is the first knife that the company produced. It’s a single action out the front automatic.

Here is a link to Microtech’s product page for the Halo VI. They give a detailed look at the knife in all its various configurations. Worth browsing if you are interested in the knife.

Here is a shot of the Halo VI next to my Microtech Stitch:

And as I mentioned before, the Halo VI is not a daily carry. In my book it’s mostly a collectible. Sure, it’s fully functional, and we will get into all of those details in the review, but it’s not a knife I see myself carrying. First of all, there is no pocket clip. Second, it has almost a 5″ blade. Third, it looks and sounds like a weapon of mass destruction.

My girlfriend, who is generally pretty cool with me having dozens of pocket knives scattered all over the house, is legitimately scared of this thing. I can only imagine how the old lady in line at the post office would react to me using this to trim packing tape. Probably by calling 911. Unless you are at a knife show there is no way you will be able to use this knife in public. It’s probably illegal for me to even take it out of the house without obtaining a concealed carry permit. On that note, you will definitely want to check your local laws carefully before carrying a Halo VI. This is not a knife that the general public will understand or appreciate.

But what the Halo VI lacks in practicality, it makes up in novelty. I think it may be the coolest knife I’ve ever owned. And I’ve owned some cool stuff over the years.

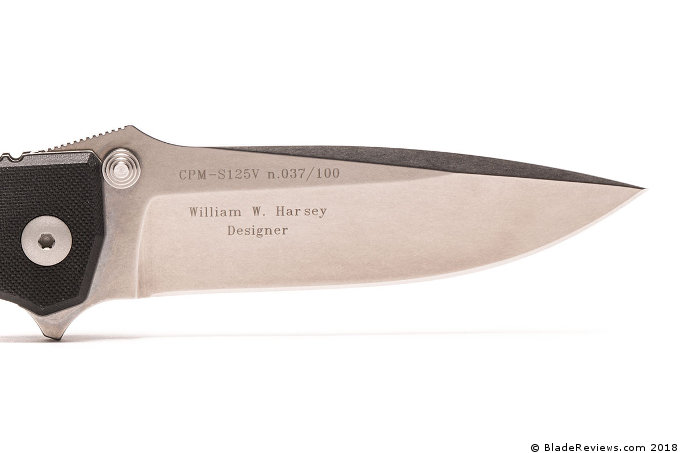

Lets check out the blade. At 4.5″ long, and over 4mm thick, it’s an imposing piece of steel. Microtech offers this in a modified drop point (or possibly a clip point) blade that they refer to as the “single-edge” or “S/E”, and they also offer this in an American tanto version with the “T/E” designation.

You also get your choice of serrations, and a number of finish options, including typical finishes like satin, bead blast, and stonewashed finishes. But they also have their “apocalyptic” finish, bronze, D.L.C., and then their painted finish shown here. Normally I’m not a big blade coating guy, but this is what was available with an unserrated edge, so that is what I got.

My blade is made from Bohler M390, a blade steel that needs no introduction at this point, seeing how we have reviewed dozens of knives running M390 by now. It’s a high end stainless steel and is widely considered to be one of the best steels for an EDC knife on the market today. It has that enviable combination of holding an edge for a long time while still being easy to sharpen. Usually a knife steel will either be extremely hard, so the edge holds a long time, but it’s very difficult to sharpen when the knife dulls. That’s not the case with M390, which is why it’s such a popular choice on high end pocket knives. It also finishes nicely, doesn’t chip easily, and is a stainless steel. It’s good stuff.

Given that this knife is a collectible, and not a practical EDC item, I haven’t done a ton of cutting with it. It came very sharp from the factory. It’s not a great slicer due to the thick blade and partial flat grind. It forms a wedge, kind of like a splitting maul, and will pop apart an apple rather than thinly slicing it like a Swiss Army Knife. But that’s OK. They didn’t design this thing to slice apples.

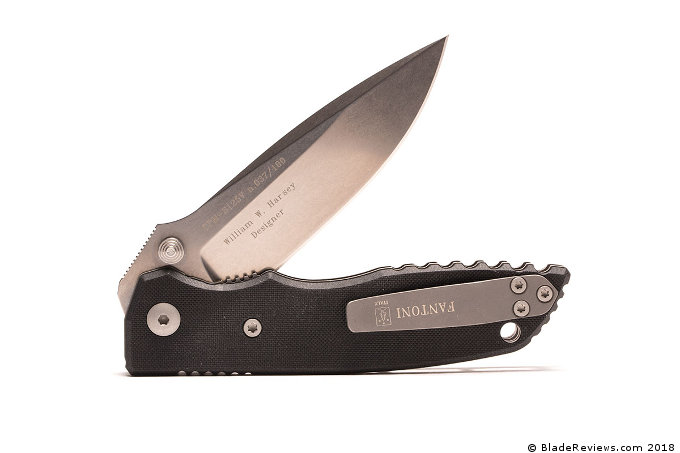

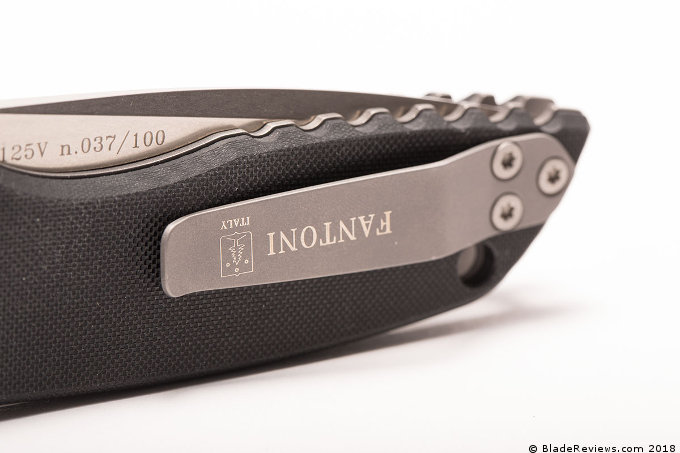

Handle and Ergonomics

A 6.125″ milled 6061-T6 aluminum handle encapsulates our big blade. If a black handle is too pedestrian for you, Microtech offers these in almost every color under the rainbow, including a couple camo variants. I’m fine with black, but then again, I’m boring.

The handle is held together with Microtech’s proprietary hardware. Normally this would be the part of the review where I bitch about proprietary hardware, but I have no intention of taking this knife apart. If there is ever a problem I’ll send it back to Microtech.

The fit and finish on this knife is absolutely top notch. It’s a precision machined piece of hardware. I can’t find a gap, unexpected sharp edge, or flaw anywhere. This may not be the most practical tool, but you have to admire how well it is built.

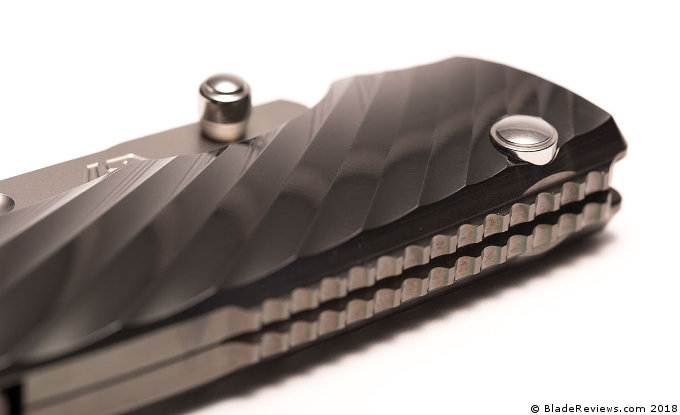

The Halo VI feels good in the hand. It’s kind of like a small light saber. There is no lack of real estate, and Microtech has created a funky pattern of jimped curves to it that adds some visual interest as well as spots for your fingers to rest.

I suppose the most practical application for the Halo VI would be in a martial arts capacity. I have no training in that regard, so can’t comment on the efficacy of the design in that role. As a layperson, I can tell you it feels fine in hand. There is plenty of room to grip this knife, and you can do so in a number of different configurations. The hard anodizing provides a tiny amount of traction. It’s not slippery, but it isn’t sand paper either.

The Halo VI doesn’t come with a pocket clip. Probably for a reason, as the last thing you would want is for this knife to accidentally deploy in your pants. Even with the new safety, I’d rather not take that risk. And with a closed length of over 6″, it’s not a pocket friendly knife anyways. I’d probably go with an Scarab or Troodon instead for daily carry.

It seems like the best option for carrying your Halo VI is with a sheath. You could requisition a large enough magazine pouch, make a sheath, or have a leather or kydex sheath made for it. There are companies that specialize in making aftermarket sheathes for the Halo VI. Linos Sheathworks currently has a kydex sheath on offer for less than $50.

Deployment and Lockup

This is where we get to the good stuff. This is a single action out the front, which means the blade fires out with a press of the button, but need to manually retract the blade when you are done by pulling back on the charging handle. Contrast this with a double action out the front, where the button is used to both open and close the blade. With the case of a single action Out-The-Front (OTF) automatic, all the spring power has been assigned to ejecting the blade. It’s a lot of fire power. Ejecting the blade of this Halo VI is arguably the single most satisfying knife event in my history as a reviewer. It’s fucking awesome.

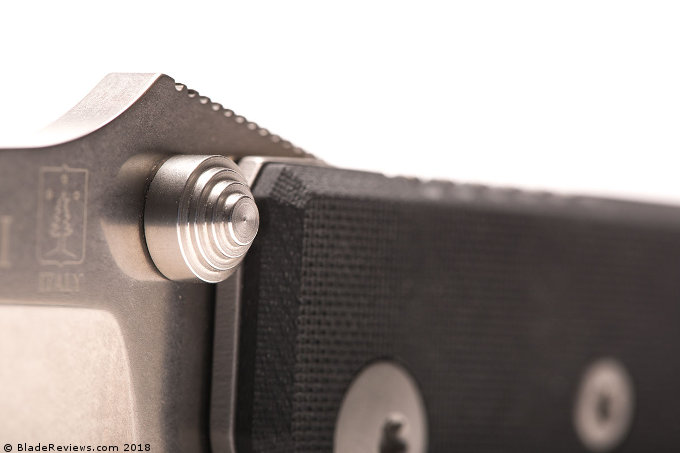

For this 6th generation of the Halo, Microtech added a small safety to the firing button. This prevents you from accidentally firing the knife. Not a bad idea, especially if you are crazy enough to carry this thing loose in your pocket. The safety is built into the firing button. You pull down on it ever so slightly, and that allows you to depress the firing button and let the blade loose. Generally I’m not a fan of safetys on folding knives. They tend to get in the way. But this safety has been beautifully executed. Purists may not be a fan of this new addition, but I think it has been done so that it doesn’t get in the way of using this knife.

For lockup, this is essentially a button lock knife. So inside there is a cam that holds the blade in place. One of the prior issues with an OTF knife, is that you tend to get blade play in them. That is especially true for the double action OTF’s I have handled. I haven’t handles a Halo V to see what kind of play, if any, is in that knife, but I can tell you this Halo VI has no play in it. It’s absolutely rock solid.

Retracting the blade is a two handed affair. First you need to depress the button. Once again that requires you to use the built in safety. With the button depressed you then pull on the charging rod to recapture the blade. It takes a good amount of force to overcome the spring tension and bring the blade back. The blade slides back in place with a sharp metallic twang. It’s a great sound. I’ve never armed a bear trap, but I would expect it to sound something like recapturing the blade on a Halo VI. It’s significant and satisfying.

The charging rod and the mechanism that holds it into the handle is worth examining. It’s all precision machined. The retaining mechanism is a couple spring loaded tabs. Everything reeks of quality and when the charging rod is in the handle all the parts line up perfectly. I’ve taken a couple detail shots of this, but it has all been beautifully done.

Here is a parting shot of the Halo VI next to my Paramilitary 2. It gives you a good sense of how huge the Halo VI is.

Microtech Halo V.I. Review – Final Thoughts

The Halo V.I. is a lot of fun. It’s also completely ridiculous, which is sure to turn off some people. I’ve been writing knife reviews since 2010, so it’s taken me almost a decade to get around to reviewing a single action OTF. This is a knife that retails for $650, so the expense is one of the reasons I delayed this purchase, but the fact that this is not a knife I can carry and use is the biggest reason why I waited so long to buy one. I like my tool knives, and this Halo V.I. is about as far away from a tool knife as I can get.

But that doesn’t make the Halo V.I. any less fascinating. Part of what makes this knife so satisfying is how well built it is. This is a design that has been refined for 25 years, and it shows. Each detail has been considered and Microtech does a fantastic job with their machining. The resulting knife is borderline obscene, but it has been so well done I can’t help but be impressed with it. Much like the Rockstead Higo I reviewed a while back, it tests the outer limits of what is possible with a production knife.

But as I have continued on my journey of exploring production knives, I’ve ventured further and further from the Benchmade Griptilians and Spyderco Delicas. They are still great, and I plan on continuing to review practical knives, but exploring the outer limits is fun too. This Halo V.I. is certainly out there, but it is so well done that I can’t help but appreciate it.

Accordingly, I can’t recommend this knife for everyone, but if the Halo VI intrigues you, I’m here to say Microtech didn’t cut any corners. Recommended for unreasonable people that that like the idea of a high end single action OTF automatic.

Microtech Halo VI – From $650.00

From: BladeHQ

I recommend purchasing the Microtech Halo V.I. at BladeHQ. Please consider that buying anything through any of the links on this website (including Amazon) helps support BladeReviews.com, and keeps the site going. As always, any and all support is greatly appreciated. Thank you very much.