I’m going to take a wild guess and say that unless you live in the Czech Republic or you’re a mega-knife nerd (like me) you haven’t heard of Acta Non Verba Knives. The name is a Latin phrase that means “actions, not words” and the company, which I will henceforth refer to as ANV, started making knives in 2018. Their headquarters is in Prague, Czech Republic, which has a long history of weapons manufacturing, going back to at least the 1400’s.

Disclaimer: this knife is a pre-production version of the A200 that was given to me by ANV knives for this review. They gave it to me because I was watching Rick And Morty (Season 3, episode 7, “The Ricklantis Mixup”) and noticed the words “ACTA NON VERBA” written on a classroom chalkboard. I sent a still of it to them on Instagram, we got to chattin’, I bought one knife I’d had my eye on for a while (the ANV Z400) and they gave me this pre-production A200 to review. I have done my very best to not let this affect the review.

General Dimensions and Blade Details

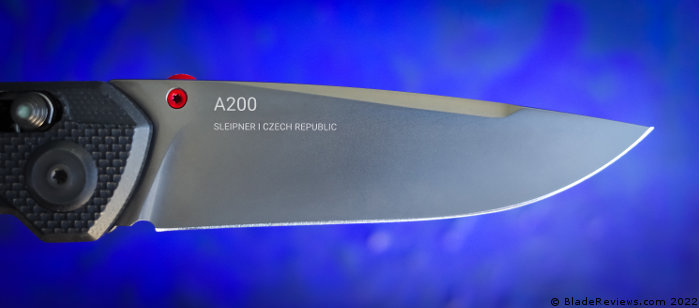

The ANV A200 has a 3.6” (88mm) long drop-point blade, and is 8.3” (210mm) open. That’s a little on the long side for some people, but I personally prefer larger knives that I can get a full four-finger grip on. I rarely buy anything smaller than this unless the blade has a large, safe-to-use choil, like on my old Massdrop Tashi Bharucha Prism pictured below.

The A200’s angular drop-point blade shape puts a subtle modern twist on an old blade style, and it’s steel does the same thing: it’s Sleipner steel, which is a modern upgrade to the very widely-used D2 tool steel, which was patented in 1927. In a nutshell, for a semi-budget steel, Sleipner has very good hardness (edge retention) and pretty good toughness (resistance to chipping). Sleipner’s two claims to fame are 1) it has a finer grain structure than D2, which theoretically makes it less prone to chipping under hard use, and 2) it’s named after Sliepnir, the mythological eight-legged horse ridden by the Norse god Odin. Odin, of course, is known throughout the modern world as being the father of Chris Hemsworth.

The blade is finished with a dark gray DLC (diamond-like coating), and is pretty slim at 3mm thick. The whole knife is full of interesting modern touches, starting with the harpoon-ish swedge towards the tip of the blade.

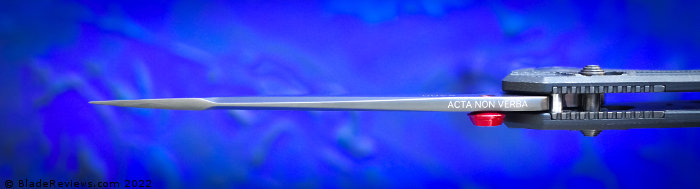

This was accomplished by removing material from the sides of the blade only and doesn’t impact the clean visual flow from tip to clip. Behind the swedge, the blade’s spine isn’t just chamfered, it’s slightly rounded- which I find to be a classy touch.

The blade’s spine, when studied from above, has a spear-shaped flow to it that has become my favorite detail on this knife. And that level of detail is all over the place on the A200 if you take the time to notice it.

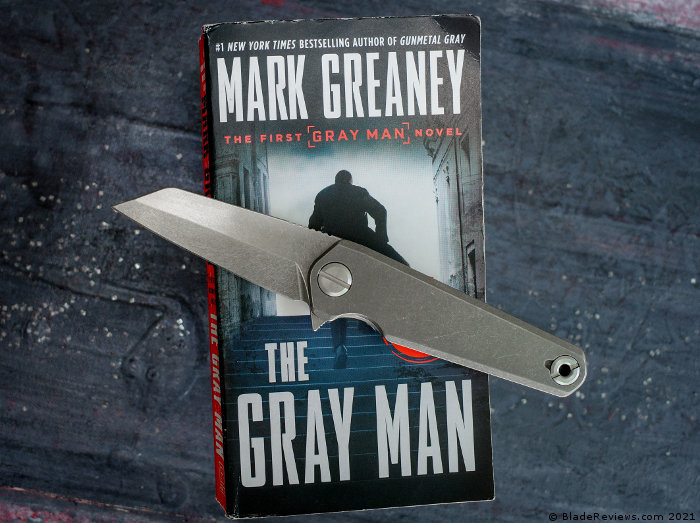

The design is modern and interesting with lots of really well-thought-out touches. When seen from beyond arm’s length, however, it’s a little plain looking, but I think that’s deliberate. According to the ANV website, the A200 is designed to be a discreet EDC knife with non-reflective surfaces and a minimalist clip, and I think that philosophy continues into the knife as a whole being not ”scary” looking to the general public. Speaking of knives that might offend the delicate sensibilities of the world’s Karens, here’s a shot of my ANV Z400 folder, which is the knife that made me notice ANV Knives in the first place.

The Z400, along with ANV’s fixed blade knives are generally a bit more flamboyant than most of their folders, especially their Anthropoid – yikes! That Fairbairn Sykes dagger shape scares even me. But generally, the ANV brand’s design language is about clean, modern lines and elegant profiles.

Handle, Ergonomics, and Pocket Clip

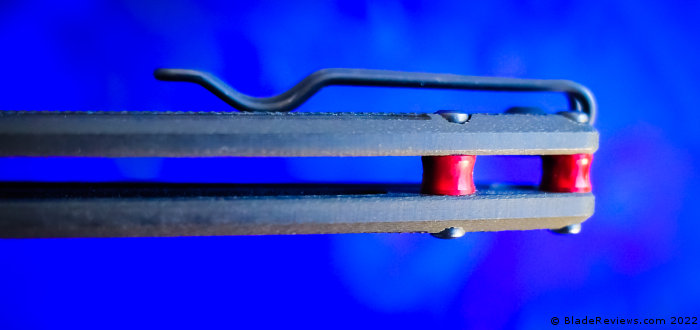

The A200’s handle is simply two pieces of machined G10 held together with two red aluminum backspacers in the rear, and the pivot in the front.

Semi-fun fact: In the above picture, to the left of the lock mechanism, you can also see the silver cylindrical magnet that I use to raise the knife off the background in most of the pictures in this review.

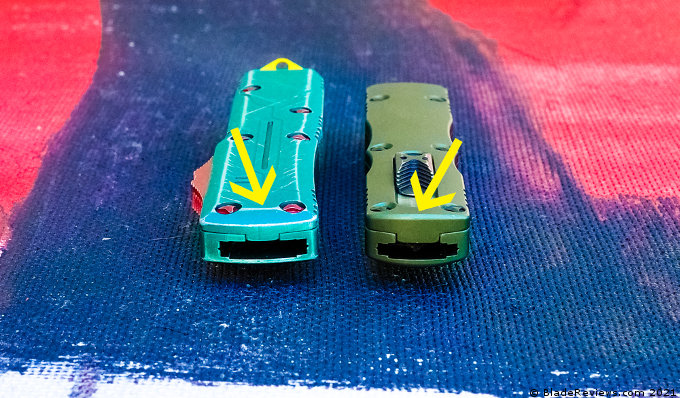

The inside face of the scales have been milled to reduce weight and to make room for the ANV “ALOCK” mechanism, which I’ll cover in the Deployment and Lockup section below. The handle is 4.7 x 1.1 inches (121 x 28 mm) long, and a quite slim .6 inch (15 mm) wide, including the width of the ALOCK sliders. The handle is long enough to provide a stable four finger grip for my my medium-large-ish hands. The handle is also wide and tall enough to fill my hand in any grip I can come up with.

The handle doesn’t have the curvy finger grooves that my mind automatically associates with ergonomic comfort, but it is indeed pretty comfortable. I attribute this mainly to ANV rounding off every single sharp corner on this knife. My ANV Z400 is the same way. I really appreciate this when I find it, mainly because not every knife maker seems to care a lot about that, regardless of price point. After reading this review of the Spyderco Matriarch here on BladeReviews.com, I snapped one up, and as a purely defensive tool, it’s awesome.

But dammit, Spyderco, every corner of the blade and lock mechanism are crazy sharp.

I don’t want to be a dick, but not bothering to round off sharp, non-cutting edges is a really clear example of why Spyderco is losing market share to high-quality knifemakers like Reate, Bestech, WE Knife Co, and perhaps now Acta Non Verba.

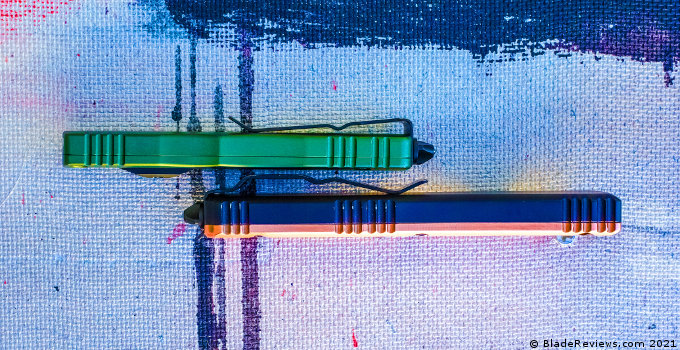

But I digress… the pocket clip of the A200 is a simple wire clip that’s SO deep-carry that the knife body doesn’t even peek out from my pocket.

By the way, the knife in this review is a pre-production version with a slightly wonky clip. From pictures I’ve seen online, it looks like the final version of the clip is perfectly symmetrical. The clip also appears to be reversible for left-handed carry, as does the thumbstud. Coupled with the ambidextrous locking mechanism, this knife can be configured to be full-blown lefty. I appreciate that ANV was able to ambi the knife with only one extra, empty hole drilled into the handle, unlike the typical Benchmade 3 extra holes, or the dreaded Spyderco 9 extra holes, as shown on the Spyderco Matriarch, three pictures above.

The wire clip has a pronounced dip near the tip.

When drawing the knife out of my pocket, I’ve found that my middle finger naturally slips into that dip, giving me good vertical pulling leverage. The clip’s dip is also perfectly placed for my index finger when I hold the knife in an upside-down stabby grip, which is how I hold the knife 0% of the time.

The ANV Z400, which is an older design than the A200, also has a wire clip, but without the dip, and it’s not nearly as easy to pull from my pocket. The Z400 also has texturing underneath the pocket clip, which tears up the inside of my pocket. I consider that to be a rookie mistake which was corrected on the newer A200 – the textured G10 that the handles are made of are machined relatively smooth under the clip. I can see a bit of wavy texture on the smooth areas, which I understand to be another pre-production quirk, since the pictures on the ANV website and the pictures on Blade HQ do not have that wavy-ness.

The handle design has a jaunty little racing stripe of rough texture running down the middle, and the rest of the G10 has been polished smooth, but still has a bit of grip to it. The stripe motif is echoed in several other ANV designs, and I think it adds to the overall modern look.

There’s another subtle touch on the handle that I really like: If you look at the two TORX screws at the butt end of the handle, they’re on the textured stripe, and are domed and uniformly stick out of the G10 about a millimeter.

There’s also a small TORX screw on the smooth part of the handle, but it’s flat topped and perfectly flush with the handle scale. That’s how much ANV pays attention to detail, and I dig it.

How does the A200 feel in the hand? Surprisingly light, but not at all flimsy. The A200 weighs 3 ounces (84 grams) which makes it by far the lightest knife I’ve owned since the Gerber LST my mom bought me for my 14th birthday. That thing was cutting-edge revolutionary back in 1984, lemme tell ya… Anyway, the idea of a thin, lightweight, knife that disappears into your pocket is once again really popular, and that’s the A200 was designed to be. It was also seemingly designed to be a direct competitor to the Benchmade Bugout.

Deployment and Lockup

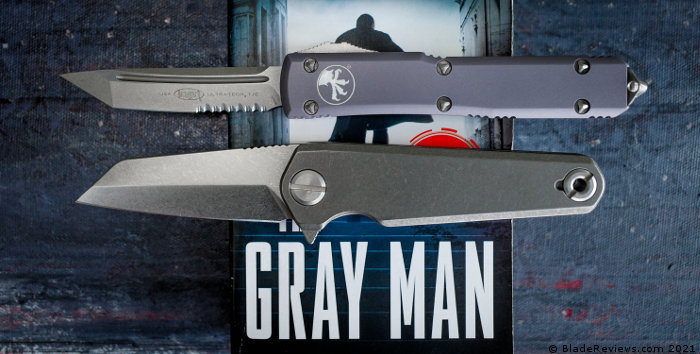

The A200 fits squarely into a pretty specific market segment: lightweight, rugged, minimalist knives with synthetic handles that use some variation of the Benchmade AXIS lock, which saw its patent expire in 2018. The A200’s main competition is the Benchmade Bugout, the Spyderco Manix 2, and the Hogue Deka. They generally cost between $115 – $160 with the A200 running at $160 retail. Apologies to the real-deal knife nerds who just bristled up when I said that the Spyderco Caged Ball Bearing lock is like the AXIS lock- I understand it’s not the same, but to the end user its pretty much the same. Nonetheless, ANV Knives calls their version of the AXIS lock the ALOCK (Hogue calls theirs the ABLE lock) and it feels exactly the same as the genuine AXIS lock on the Benchmade Adamas pictured below.

To open the A200, you can rock the blade open through a relatively light detent using the thumbstud, or you can pull back on the spring-tensioned locking disc and let the knife freely swing open until the blade locks into place. With a little practice, it’s easy and pleasurable to swing the knife back and forth, using on/off pressure on the locking disc to effortlessly snap the blade open and closed. It’s fun, and annoying to anyone else in the room. Either way, the action is smooth, despite pivoting on old-school washers instead of tiny ball bearings, as has become very popular in the last several years. When the blade is locked open, there’s zero blade play in any direction and I would feel confident abusing this knife beyond it’s intended medium-use design.

There is one thing that I really don’t like about the A200- the placement of the thumbstud.

The thumbstud itself isn’t the problem: it’s comfortable, its concave shape feels great under my thumb, and it has a neat little dab of glow-in-the-dark paint in the center. The problem is that my love of knives has a lot to do with aesthetics, and specifically the “flow” of a knife’s lines.

Below are some of my knives that I consider to have particularly elegant profiles.

Anything stick out (or up) to you about the A200?

Why in the name of Rugiaevit would these detail-obsessed Czechs totally blow the superb profile of the A200 by having the thumb stud stick up above the blade spine like this? To show they prioritize function over form? To deliberately, personally, confuse me? I don’t know, and it’s certainly not a dealbreaker, but it bugs me.

Acta Non Verba Knives A200 Review – Final Thoughts

So why would anyone in the market for a lightweight, rugged knife drop $160 on the ANV A200 over a similarly featured and priced Benchmade Bugout (check out the super fun 3D custom configurator!), a Hogue Deka, or a Spyderco Manix 2? Those brands have generally good reputations and premium cachet compared to ANV, which seems to be basically unknown in the United States. The answer for me is that I’ve handled all the knives named above, and although they’re all good knives, I like the A200 better because of its subtle refinements.

ANV did a bunch of stuff they didn’t have to – like the flush screws on the body of the grip, and rounding the corner of the blade that’s exposed when the knife is closed (circled below).

On the Spyderco Matriarch, you can cut yourself on that corner. I said that ANV doesn’t have to do all that stuff, but maybe they do- maybe as a new company they understand that to get a slice of the pie they have to do some things better than the heavy hitters in the industry. Or maybe they’re just super OCD about chamfering.

Either way, I’m happy because I have a well-made piece of functional art that I can flick open and closed all day without annoying anyone while I work remotely in my covid Fortress Of Solitude (aka my garage), editing silly reality TV shows.

Thank you to Sara O’Neil for the use of her painting.

Acta Non Verba Knives A200

From: BladeHQ

Editor: I recommend purchasing the Acta Non Verba Knives A200 at BladeHQ. Thank you for reading.