Last Updated: November 30, 2019

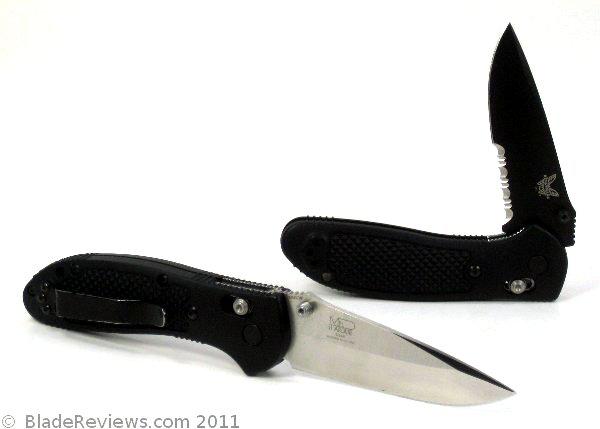

The Benchmade Griptilian is a household name in the knife world. It is one of Benchmade’s most popular designs and it appears in countless variations.

Buy the Benchmade Griptilian at BladeHQ

No products found.

For many, this will be their first “real knife”. A gateway blade into the world of high end pocket knives. It was one of my first nice pocket knives, so it holds a special spot in my heart. What’s interesting, is that I still have and use this knife almost a decade later. I originally wrote this review back in 2011, so this is a very long term hands-on review of the Benchmade Griptilian.

General Dimensions and Blade Details

The full size Griptilian has an overall length of 8″, a 3.45″ blade, weighs 3.25 ounces, and is made in the USA. This isn’t a small knife, but Benchmade has managed to keep the weight down. By way of comparison, the Mini Griptilian has a a 2.9″ blade, an overall length of 6.78″ and a weight of 2.56 ounces.

If you are at all like me, you may be on the fence about whether to get this full size Griptilian or the Mini Grip. I actually purchased a Mini-Grip first, but I ended up swapping it out for a full size because I wanted something with a full size handle. I know a lot of people who prefer the Mini-Grip for an EDC knife. It’s all a matter of preference.

Depending on whether you are looking at the thumb hole version or the thumb stud version the knife will have either a sheepsfoot blade with a thumb hole or a drop point blade. Both blade shapes come in 154CM stainless steel and both blade types will have a long hollow ground edge with plenty of belly. The drop point edge is very attractive to me, so that is what I ended up purchasing. It has a swedge that finishes in a fairly stout tip – good for piercing tasks. The knife was extremely sharp out of the box. All in all this is a very nice blade which is great for EDC chores.

The standard Grip comes with a blade made of 154CM stainless steel. 154CM is a highly regarded stainless steel manufactured by Crucible Industries in the USA. While fancier (more expensive) steels have come on the market in recent years, I still appreciate 154CM because it takes a nice edge and is easy to sharpen. I actually prefer 154CM over S30V in many applications because 154cm is so easy to sharpen, while S30V can be stubborn to sharpen. 154CM is a proven steel and is a good fit for a working man’s knife like the Griptilian.

Handle, Ergonomics, and Pocket Clip

The handle of the Griptilian is made of Valox, which is an injection molded high density resin. It’s plastic. I know some people don’t care for the Valox handle because it has a lightweight and the plasticy feel. Personally, I think it is a practical choice for the handle as the material is both lightweight and tough, but I understand how fans of more substantial knives could be turned off by the product.

After years of people complaining, Benchmade finally issued a G-10 version of the Griptilian and Mini Grip in late 2015. I still like the original plastic handled version, but the G-10 version is beautiful and definitely an upgrade. Check out my review of the G-10 Griptilian here.

This handle has a closed back design, which means it is a little more difficult to clean than a knife with pillar construction. The handle is held together with screws and everything is nicely finished. Benchmade makes a ton of these knives and they seem to have their manufacturing and quality control protocols dialed in.

As far as ergonomics are concerned, the handle is chunky and covered with texturing. I would expect no less from a knife called the “Griptilian”. There is a run of jimping on the spine of the blade, and little jimping in the plastic placed strategically around the handle. The knife feels good in the hand and there is no lack of traction. I have used my Griptilian for years now and it continues to be a solid performer.

The Griptilian comes with Benchmade’s standard steel pocket clip. The clip is a classic no-nonsense design that has stood the test of time and can be found all over Benchmade’s lineup. The handle is drilled and tapped for ambidextrous tip up carry. All in all this is one of my favorite clips. It has great retention, buries deep and looks normal. The only potential issue is that the black finish will quickly began to wear like mine has. That is not an issue for me, and if you send the knife in for sharpening, Benchmade will include a new clip.

How does the Griptilian carry? While the Griptilian is lightweight for its size, this is a thick knife. At over half an inch thick you will likely notice it in the pocket. All said, it carries well. The standard clip is not a deep carry pocket clip, but it buries most of the knife into your pocket. Here is a pocket shot:

Deployment and Lock

Whether you opt for the version with thumb studs or the thumb hole, the Griptilian deploys with alarming speed. Seriously, this is one of the fastest deploying and smoothest opening knives I own and it’s one of my favorite features of the knife. I’ve taken mine apart for cleaning a couple times, and Benchmade has installed some of the biggest phosphor bronze washers that I have ever seen on a folding knife. No doubt this is part of the reason why deployment is so smooth.

The Griptilian uses Benchmade’s axis lock which I have written about quite a bit in the past. It’s an excellent lock and it really works well with the Griptilian. There is a lot of weight in the blade which makes it easy to really flip the knife out fast and it makes for a solid lockup. Also, the axis lock gives you a variety of ways to open and close the knife. I find myself playing around with the deployment of this knife a lot. It’s a durable locking system that allows the knife to easily be open and closed with one hand.

Benchmade Griptilian 551 vs. Benchmade 551-1 G10 Griptilian

As I mentioned in the handle section, Benchmade released the 551-1 G10 Griptilian in 2015. This was after years of people complaining about the plastic handles of the original 551. I have both the G10 and regular version, and wrote an in-depth review of the G-10 Griptilian.

Here is a picture of the original Griptilian, the 551-1, and a Doug Ritter Griptilian with Wilkins GRIP aftermarket G-10 handles:

The G-10 version is awesome, but it’s also about $100 more than the regular version. Naturally, people want to know if the G10 version is “worth it”. I can’t really answer that, because everyone is different and value is relative. Some people will see the value in the G-10 version, some people wont, and some people won’t even see the value in the regular FRN Griptilian.

I will say that the 551-1 is immaculate. Benchmade did an absolutely beautiful job with the knife, and I can easily see where the extra money went. They didn’t just slap on some G10 handles, they considered every aspect of the original Griptilian and tweaked it when building the 551-1. It’s a wonderful knife. If you have the money and interest, then my suggestion is to spring for the G-10 version. With that said, the original 551 is still as serviceable as it ever was, and remains one of my all time favorite pocket knives.

Benchmade Griptilian vs. Mini Griptilian

Ok, so you have decided that you want some sort of Griptilian. Often the hardest part is choosing between a full size and a mini. I recorded a comparison video for you to help make the decision a little easier:

At the end of the day, both the full size and Mini Grip are excellent knives. I can easily justify having both in my collection. With that said, if you have to pick one, then my blanket advice would be to buy the mini-grip if you plan on carrying it in a suburban environment (ie, if you plan to use it at work, and you work in an office). The full size Griptilian is a good size knife, and some will consider it threatening if you use it in public.

Here is a size comparison with the Mini Grip:

If you can get away with carrying a bigger knife and like bigger knives, then go for the full size Griptilian.

A Few More Comparisons…

Since the Griptilian is such an iconic knife, people can’t help but compare it to other knives. I’ve used it as a reference piece in a number of articles.

One obvious comparison is with the Spyderco Paramilitary 2. I actually wrote an entire article comparing the Para 2 with the Griptilian. Since I went into such detail in that article, I won’t re-hash it here, but it’s worth checking out if you want to compare the 2 knives.

Another interesting comparison is with the Benchmade Bugout:

I like the comparison because in many ways the Griptilian was the original lightweight folding knife, and the Bugout can almost be considered a refinement. The Bugout came out at least a decade after the Griptilian, and it benefits from a lot of refinements. It’s thinner, lighter, with blue anodized standoffs and a super thin blade.

The Bugout is a more expensive knife, but I really like it. I think it’s worth the extra money. Of course, there is room in my collection for both knives.

Benchmade Griptilian Review – Final Thoughts

The Benchmade Griptilian has a well deserved reputation of being both an outstanding pocket knife, and a modern classic. Benchmade started with a timeless and functional design, and built the knife to be lightweight, fast, and functional. The thickness of the handle and choice of plastic for the handle material will be turn offs for some, but personally I like how the the knife feels in hand, and have no problems with the choice of handle material. And these days we have the G-10 551-1, so if you don’t like the black plastic, go for the G-10.

My Griptilian has seen years of use, and it still finds a lot of time in my pocket. This is my highest form of endorsement. I have owned my Griptilian since 2011, and I still have it in my regular rotation. This is after reviewing hundreds of pocket knives. Over that course of time I have bought and sold dozens and dozens of knives. I still have my Griptilian and I still use it. That alone should tell you something.

I recommend the Griptilian if you are in need of a larger EDC knife or utility knife. If you are looking for a smaller knife, then check out the Mini Grip. Both are great. If you want something higher end, then go for the 551-1, or the 556-1. At this point there is something for everyone in the Griptilian lineup. You can’t go wrong with the Griptilian.

No products found.

I recommend purchasing the Griptilian from Amazon or BladeHQ. Buying anything through any of the links on this helps support the website at absolutely no cost to you. Any and all support is greatly appreciated. Thank you very much.