Last Updated: August 12, 2019

Today I am taking a look at the ultra classy Benchmade Dejavoo. Designed by the late Bob Lum, known for his simple and elegant designs and the Dejavoo is no exception. Now that he is no longer with us, his custom pieces are becoming incredibly difficult to find so for many the only way to experience his work is through a collaboration like he did here with Benchmade.

Purpose

As far as utilitly is concerned, the Dejavoo is in an interesting position. While I wouldn’t put it directly in the tactical role (not a lot of traction on the handle or spine, not the strongest lock), it could certainly fill that void in a pinch. Also, it’s a little large for a so called “Gents Folder,” although I think it’s a fine looking knife and is suitably refined for that role. For the same reason it wouldn’t make the top of my list for an EDC knife, although it is relatively light and would make a pretty exotic EDC blade (the “mini” is a good size for EDC). Yes the Dejavoo is somethng of an anomaly and I think for most this is more of a collectible knife, especially since Lum’s passing (RIP).

General Dimensions and Blade Details

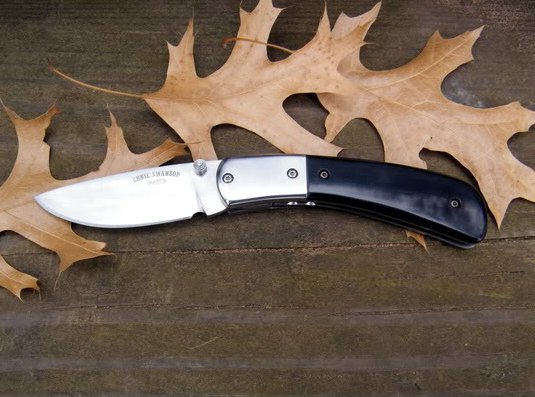

The full size Dejavoo sports a blade just under 4 inches (3.95″ to be exact) with an overall length of 9.12″ and a weight of 4.10oz (3.2″ blade and 3.5 ounce weight on the 745). 4 ounces is impressive when you consider how much knife you are getting here… and believe me, you are getting plenty of knife. Not only is the Dejavoo big, but it’s beautiful. The long slender blade arcs slightly and a thin swedge trails almost the entire length of the spine. It’s a beautiful, almost peaceful design that is distinctly “Lum” and innately appealing. I know the looks of this knife has enchanted many over the years – even the name “Dejavoo” hints to some magic lurking beneath the steel and G10.

And speaking of steel, the blade on the 740 is made of a thick piece of S30V, a high end steel that I like because of the great combination of edge retention, corrosion resistance and ability to take a razor sharp edge. Benchmade accentuated that great steel by giving the Dejavoo a full flat grind and a really nice factory edge.

Handle, Ergonomics and Pocket Clip

The handle of the Dejavoo is also pretty special. Just by looking at the pictures you can see the attention to detail Benchmade put in here. It has full steel liners with some very nicely finished G10 scales laid over it. The G10 is relatively smooth, and lightly finished to show the “grain” while still supplying some grip. It adds another layer of class to look of the knife. The handle is a semi flow through design, and uses a black backspacer en lieu of pillars. Everything is bolted together so you can take this knife apart if need be. The liners are also kind of special; the locking liner is made of titanium and the non locking side is made of 420J stainless steel (very tough) that has been milled out to lighten up the knife and help it feel “alive” in your hand.

I also have to say that the Dejavoo has some great ergonomics. First of all, the 740 is a good sized knife, so you are going to have plenty of real estate to accommodate various grips. Indeed, the Dejavoo feels good in either a forward or reverse grip and I don’t find myself struggling to find space for all my fingers. Also, the design itself is great. Your hand will fall in place, it’s not awkward or uncomfortable at all.

From a traction standpoint, this isn’t the grippiest knife. It’s a smooth handle, obviously designed for form over function. If you are buying this as a hard core “tactical knife” I am sure you would be disappointed. From a collector knife or even an EDC knife standpoint, this really isn’t an issue. Additionally, you will find jimping to be woefully absent… again, not really an issue in my opinion. There is a rather prominent thumb ramp (which is mirrored in the choil area, almost appearing like a “hilt” when the knife is closed) and it catches the hand nicely. Again, obviously a nod to the form over function approach that Benchmade sometimes takes with their higher end knives. In my opinion, if you want a knife that you can take into a foxhole with you, consider something built for the task, like an Emerson.

It is a nice looking clip made of a piece of folded over stainless steel. The clip rides very low, it has great retention and is well polished. My only beef is that it is right side tip down only.

Lock-up and Deployment

The Dejavoo features a thumb hole aka a “Spyderhole”. I love thumb holes, they are great designs, and it works really well here – both functionally and aesthetically. I am not sure what the deal is in terms of trademark infringement with Spyderco. Ironically, hardcore Spyderco fans may actually not like this knife because of the use of the Spyderhole, as they may view that Benchmade ripped off the design. Eh, that is the subject for another post (or perhaps a law review article) so I’ll just say “it is what it is.”

One thing to note is that the blade retention can use some work… actually it could use a lot of work as the blade practically falls out of the handle. That is a problem, especially if you are going to carry the knife loosely in a pocket or bag. It’s weird because my 2 biggest problems with the knife; tip down carry, and weak blade retention, kind of cancel themselves out because if you use the pocket clip, it’s going to be hard to accidently stab yourself when carried tip down.

As for the lock, Benchmade went with a liner lock here. I can see an argument for wanting an axis lock with this knife (and yeah, I love the Axis lock), but in truth, I think it would make for a totally different looking knife. There are plenty of options for axis lock fans (Griptilian, Onslaught, etc), and this stays true to the original Lum design, so a liner lock is fine with me. Lockup is nice and tight, although the lock bar itself is not the strongest I have seen. People have been fixing both the weak lock and retention by wedging a small piece of paper between the scale and the liner down by the butt of the handle.

Value

As far as value is concerned, I think price (just north of $120 for the model shown here) is fair when you consider the great materials and fit and finish. The smaller version sells for a little less and might make for a more practical EDC type knife. I think they are both fairly priced.

Benchmade Dejavoo Review – Final Thoughts

Well, what can I say? The Dejavoo is such a beautiful knife it makes it easy to ignore the little flaws. The major flaws, issues with retention and lockup, can be easily fixed with a small piece of paper wedged in between the lock bar and the scale. Color the paper with a Sharpie and you won’t even see it. Some might find modifying a brand new $100+ knife with a post-it-note to be a cardinal sin. However, there is so much that the Dejavoo does right, and it does it with class… it truly is worth a second look.

- Ergonomic Handle Design Round

- Thumb-Hole Opener

- Ultra-Premium Blade Steel

- Country of origin: USA

Photo Credits: Many many thanks to Voygin for use of the beautiful photos. He does amazing work and has a very impressive collection.