Last Updated: August 3, 2019

I hope the regular readers are interested in high end knives, because the next few posts are all going to be doozies. The TM-1 is so mythical a knife, that it isn’t even out yet, although LionSteel tells me that they will be introducing it to market any day now. I was fortunate enough to snag one of the pre-release samples on display at the 2014 Blade Show.

Buy the LionSteel TM1 at BladeHQ

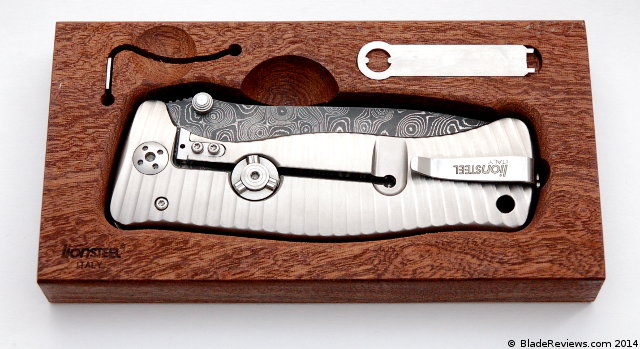

As a lover of knives, I had an extremely tough time putting down the TM-1 LionSteel had on display at their booth. As a lover of deals, I couldn’t resist asking whether they would be willing to part ways with one for purposes of review. Gianni, co-owner and CEO of LionSteel, was kind enough to oblige me. That said, I do need to make clear that this knife was one of the 4 or 5 display pieces sitting at the Blade Show booth, and it has been handled by hundreds of people over that weekend. As such it has a few scuffs and carry marks, and I of course have been carrying and using it myself as well.

The TM1 is another knife in LionSteel’s SOLID® line, which means that the handle has been milled out of a single block of material. In the past titanium has been LionSteel’s handle material of choice, and I examined my titanium-handled SR-1 not too long ago. This time around LionSteel has decided to use either carbon fiber or micarta. Being the material girl that I am, I of course opted for carbon fiber. The carbon fiber is handsome and makes the knife much lighter than my SR-1 (which is about the same size).

Perhaps even more interesting than the material selection is the fact that this time around LionSteel wanted to make a monolithic handled knife with a back lock and IKBS bearings; two firsts for the company. I have been admiring the knife for almost a month now and I am still unsure as to how exactly they pulled that off. Regardless of what draws you to the TM1, there is something to admire. And I feel very fortunate to share some early thoughts on this brand new knife.

General Dimensions and Blade Details

The TM1 has an overall length of 8.07″, has a 3.54″ blade, and weighs 4.48 ounces. Much like when handling the Zero Tolerance 0454, another carbon fiber handled knife, one of my first remarks when picking up the TM1 was how light it felt. The knife feels deceptively light for its size, and is way lighter than a titanium handled counterpart. This is a largish EDC knife in my book. Not only is it a pretty long knife, it is thick and wide as well. That said, the TM1 was definitely built with use in mind. Construction is stout, the handle and blade are capable, and the light weight means that it is actually something that can be carried.

The TM1 has a unique reverse tanto blade. Reverse tantos are uncommon. Arguably the best known production knife to feature the reverse tanto blade shape is the Benchmade 940, which happens to be one of my favorite Benchmades. So the blade profile of the TM1 is different from most of the knives in my collection, and is a welcome divergence from all of my drop points. The reverse tanto not only looks unique, but it is quite practical too. You get all of the belly of a drop point with the fine tip of a tanto. LionSteel further enhanced the usability of this knife but giving it a full flat grind, which gets nice and thin behind the edge. This isn’t just a show piece, this is a practical tool.

LionSteel elected to equip the TM1 with a Sleipner stainless steel blade. This is my first real experience with Sliepner, and it has been fun to put this knife through its paces. I am not particularly interested in the chemistry of the steel, but here is a link to the data sheet so you can check all of that information out.

In practice I found Sliepner to perform well for daily carry tasks. Like I mentioned in the intro, this was something of a scratch and dent model, so I had no problem with beating on this knife a little (the first scratch is always the hardest). I worked with cardboard, wood, paper, and plastic, and the knife never had a problem. When the edge did start to slow down it quickly came back after stropping. My final thoughts on Sliepner are still in the works, but so far this steel seems very promising. No issues with rust or corrosion either.

My knife did come with a black blade coating. I am pretty sure it is a black oxide blade coating, and it has held up really well under use. Granted I haven’t use this knife to open up a can of Chef Boyardee, but so far there is no scratching or visible signs of wear.

Handle, Ergonomics, and Pocket Clip

Obviously handle construction the reason to buy this knife. Milled from a solid block of micarta or carbon fiber (shown here) handle construction is impressive, to say the least. Every corner has been masterfully chamfered (in some cases it has been so decoratively), and the handle is contoured for comfort and style. The end result is beautiful and displays the carbon fiber weave in a number of different facets. The workmanship is flawless; all the lines are crisp and clean. My satisfaction with the execution of the carbon fiber handle cannot be overstated.

The TM1 feels at home in my hand. It’s a stout knife, with plenty of handle and an abrupt finger choil. The body of the handle gently swells to fill the palm, and the absence of jimping is not a problem for me. Despite the apparent lack of a dedicated “traction plan” the knife magically manages to remain in my grasp. This is a comfortable and fully functional handle.

The TM1 features an ambidextrous deep carry pocket clip. This is the same clip found on the SR-1. Mine has been given the same black oxide coating as the blade (so far no wear), and is held in place with a carbide glass breaker. SR-1 owners will attest that this is a very nice pocket clip. It is discrete and holds the knife very securely in your pocket. The fact that it is mounted on the butt of the handle is very elegant. There are no extra holes in the handle of the knife and I love the simplicity and practicality of this clip design.

For a larger and bulkier knife the TM1 does carry well, in part because it has a well implemented and secure pocket clip, and in part because it is so lightweight for its size. This is definitely a knife that can be carried.

Deployment and Lockup

The TM1 makes use of a thumb disk to open the blade. This is probably my least favorite aspect of the knife. It works fine for slow and purposeful openings, but I have found it impossible to flick open. I guess at the end of the day that is perfectly acceptable, but this is a knife I would love to flick open given the IKBS bearing system and the massively satisfying “thwack” sound the knife makes upon deployment. It makes almost a chirping noise, kind of like the Sage 1, which also happens to feature carbon fiber. My guess is that they opted for the thumb disk so that they wouldn’t spoil the lines, and I suppose that is a worthy compromise.

My knife locks up without even a hint of bladeplay. Again, the sound this knife makes upon locking up is very unique, and very satisfying. Upon disengagement of the lock bar the blade falls about halfway closed, where it can then be shaken completely shut. I have never handled a lockback that smooth before. No doubt this is due in part to the use of an IKBS bearing system, and LionSteel definitely deserves some kudos for this. The large decorative pivot is very smooth, and the action is a lot of fun. I still have no idea how they got all of those bearings into this thing.

It is worth noting that my blade is perfectly centered.

LionSteel TM1 Review – Final Thoughts

The TM1 is the third addition to their integral line, and I think it is my favorite. I say that because in my opinion this knife is meant to be used; a vibe I don’t really get from my TiSpine or my SR1. LionSteel has managed to elevate the humble back lock to a drool worthy, collector status knife yet they have also kept it durable and functional. The lightweight handle makes this a knife that I actually want to pocket and use, while the TiSpine and SR-1 are knives that I want to enjoy while sitting on my couch. Plus, titanium scratches easily, and this carbon fiber really hides wear well. Same with the black oxide coated blade.

I think LionSteel is really doing some exciting things. While other manufacturers seem to be caught in something of a creative rut, LionSteel’s creativity and willingness to push the envelope further elevates themselves as serious contenders in the US production knife marketplace. And I don’t think I am the only one to notice this. LionSteel won the 2014 Blade Show manufacturer of the year award, and their HiJinx collaboration with CRKT and Ken Onion netted them a 2014 knife of the year award as well. As I look towards their next move, I can’t help but wonder if we will see some of this technology filter down into some budget minded products. I doubt we will see a 4-axis machined carbon fiber handled knife retail for under $200.00, but if there is one thing I have learned about LionSteel, it is to expect the unexpected.

Given the premium price tag, this knife won’t wind up in everyone’s collection, but I definitely recommend it if the TM1 is one that you want to buy. This is an amazing knife and I am very impressed by it.

Lionsteel TM1 – From $400.00

From: BladeHQ

- MADE IN ITALY by LionSteel, one of the world's premier knife manufacturers

- KNIFE HANDLE is precision machined from a solid block of Micarta for extra sturdiness and strength

- BLADE is made from Sleipner steel, a chromium/molybdenum/vanadium alloy which is a variant of D2 steel

- INCLUDES tungsten carbide glass breaker and an ambidextrous pocket clip

- DIMENSIONS: Blade Length 3.54", Blade Thickness: 0.18", Total Weight: 3.5 oz.