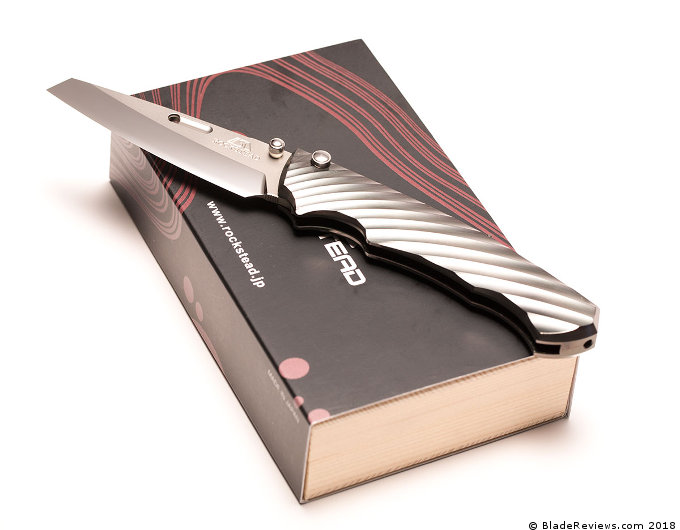

The Fantoni HB-01 is a collaborative design with William Harsey Junior. Harsey is a well known American designer and custom knife maker. He’s notably popular for producing several knives for, and with the collaboration of divisions in the U.S. Special forces. This design has its production roots in a discontinued iteration put out by Beretta knives.

General Dimensions and Blade Details

The Fantoni HB-01 has an overall length of 9.37” (238 mm), a 4.13” (105 mm) blade, weighs 5.93oz (168 g), and is made in Italy by Fantoni Knives. This is a large folding knife. Fantoni also makes the HB-02, with a smaller more EDC friendly footprint.

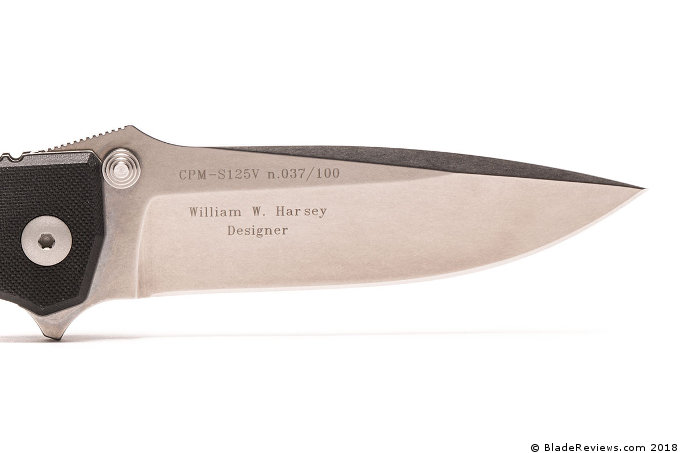

The limited edition model’s blade is made from CPM S125V, a very exotic, extremely wear and corrosion resistant stainless steel from Crucible. Notoriously difficult to machine on a production level; only a run of 100 of these limited edition knives were produced. Fantoni also offers a standard HB-01 and smaller HB-02 in CPM S30V with black, forest green or tan scales.

The blade steel has been made possible through Crucible’s Powder Metallurgy (C.P.M) process. It currently has the highest Carbon and Vanadium available in a stainless steel. To make a comparison against another popular Crucible “super steel” S30V, S125V has over twice the amount of Carbon and nearly four times the Vanadium.

Here is a comparison between the popular CPM S30V, 440C and CPM S125V

| Steel | Carbon | Chromium | Vanadium | Molybdenum | HRc | Wear Resistance | Corrosion Resistance |

| CPM S125V | 3.30 | 14.00 | 12.00 | 2.50 | 61-62 | 39.00 | Very high |

| CPM S30V | 1.45 | 14.00 | 4.00 | 2.00 | 61-62 | 9.50 | High |

| 440C | 1.20 | 16-18 | – | .75 | 57-58 | 4.0 | Low |

To yield the maximum performance from the alloy Fantoni utilizes an exacting heat treating process. First the steel is brought up to 2050ºF (1121ºC) (Austenite) with a 15 minute hold to homogenize the material. An inert gas quench is executed to avoid surface oxidation. It is then processed through a freezing treatment of -176ºF (-80ºC) for three hours to maximize the transformation from an Austentic to Martensitic phase. Finally two complete tempering procedures bringing the blades up to 356ºF (180ºC) for three hours and back down to room temperature results in the final hardness of 61-62 Rockwell.

Conservatively speaking, users can easily expect over twice the performance than that of S30V. When considering the specs this would likely be more like 3-4 times however there isn’t enough empirical evidence to fully claim that (yet).

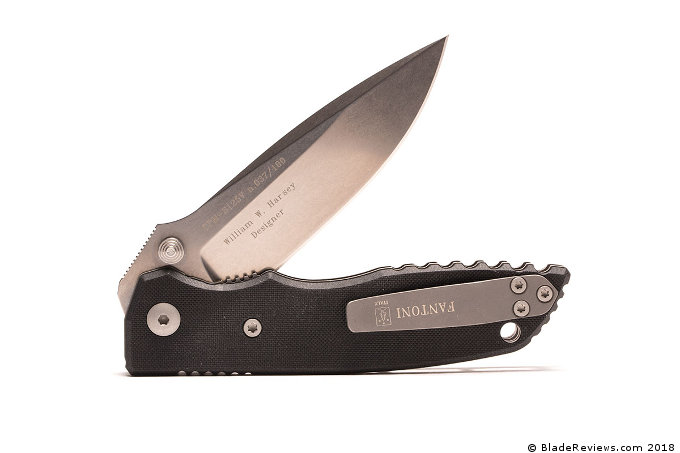

The blade pattern is a very lean drop point that produces a fine tip optimized with a long swedge. The grind is a high flat that is finished with a secondary, edge bevel. As to be expected, with the steel’s specifications, the blade is very sharp and holds its keen edge for a long time. This is helped along by the high hardness. In fact, with all the cutting that I’ve been doing, I haven’t had to touch it up yet. When it does come time to sharpen It would be nice if there was a choil since I prefer an even edge right up to the plunge.

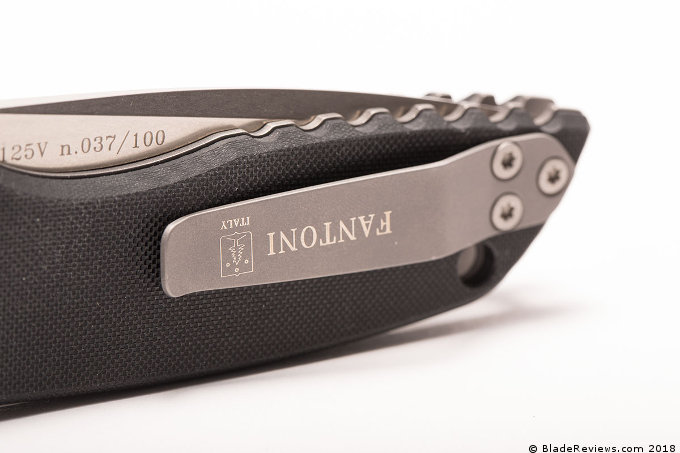

Cut from 4mm stock and with a length of 4.13” the blade strikes an exceptional balance between strength and function. It also has plenty of reach if needed. A fine stone-wash gives a clean, finished appearance. Fantoni’s logo and word-mark appear on one side of the blade while the designer name, steel type and unique number are on the other. This knife is 37 of 100.

Handle, Ergonomics, and Pocket Clip

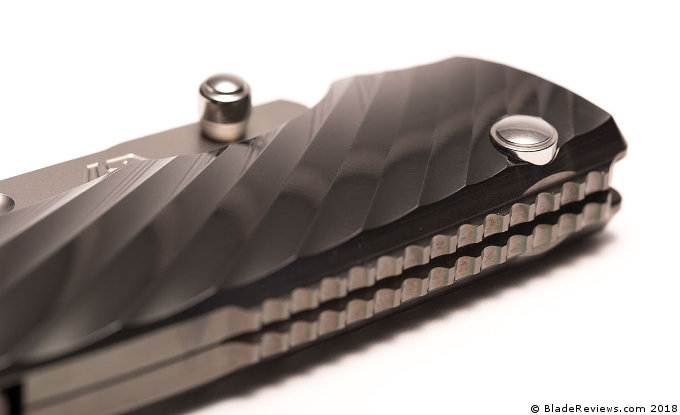

The knife has great ergonomics. At 5.25” there is plenty of handle real estate to have a full grip with or without gloves. Slight grooves for your first two fingers followed by some coarse, deep jimping for the rest lock things in place. The inner jimping wraps around the pommel working as a grippy thumb rest in a reverse grip. The blade’s spine forms a ramp with finer, square slotted jimping followed by some corresponding texture on the handle for your thumb. For good measure, the G10 Scales have a fine, high-traction peep ply texture.

The handle is an open back, pillar construction. This will allow for easy cleaning and helps cut weight. At an over-all length of 9.37” the knife sits at a modest 5.93 oz. For its size it has enough heft to give a satisfying, quality feel and confidence in use without adding dead weight.

For carry there is a tip up, ambidextrous pocket clip. It works well and, with the G10’s texture has a great retention. The clip’s fairly low and wide profile doesn’t feel obtrusive in use which is a huge plus. The surface is blasted and laser etched with the Fantoni Logo and word-mark adding a tasteful detail.

Deployment and Lockup

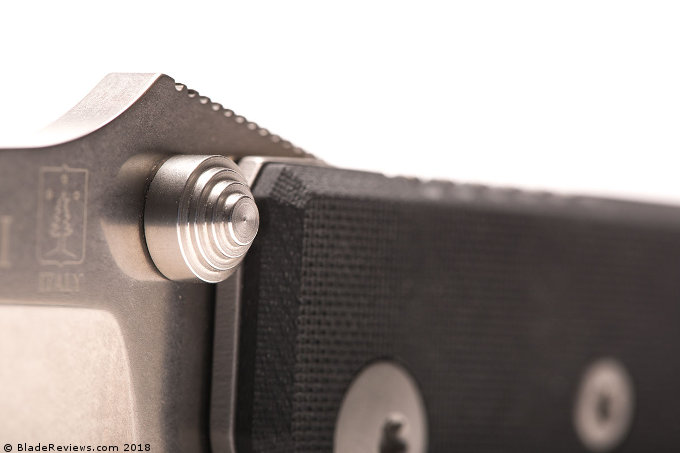

For deployment there are dual, ambidextrous thumb studs. These also serve as the stop-pin when the blade is both open and closed. Because of their function, the studs contact the edge of the scales in the closed position. Regardless, their size coupled with a tiered cap makes deployment easy.

While there is a flipper like protrusion, the knife isn’t a true flipper and requires a healthy wrist flick if you want to open it this way. On opening the tang meets a solid, play free titanium liner lock. A deep texture on the lock leaf allows for easy, one handed closing. The pivot is smooth and the components travel against phosphor bronze washers.

Fantoni HB-01 Review – Final Thoughts

The HB-01 is the third Fantoni knife I have reviewed and solidifies the company as one of my favorites. A strong focus on the fit, finish and foremost function, strips away superfluous details. High end materials, an exceptional heat treat along with William Harsey’s experienced time proven design has produced a true modern classic. The only downside to this folder is its extremely limited run of 100. If you are lucky enough to own and use one I’m sure it will satisfy.

Fantoni HB-01

From: KnifeArt

Editor: I recommend buying the Fantoni HB-01 at KnifeArt. Please consider that purchasing anything through any of the links on this website, including links to Amazon and BladeHQ, helps support BladeReviews.com, and keeps the site going. Any and all support is greatly appreciated. Thank you very much.

Additional Specifications

Total Length: 9.37” (238 mm)

Weight: 5.93oz (168 g)

Blade:

Length: 4.13” (105 mm)

Thickness: .157 (4 mm)

Steel: CPM-S125V

Hardness: 61-62 HRc

Finish: stone wash

Handle:

Length: 5.24” (133 mm)

Thickness: .55” (14 mm)

Liners: 6AI4V Ti liners

Scales: black G10

Clip: Ambidextrous 6AI4V Titanium Tip Up

Lock: Liner

Made In Maniago, Italy

Photo Credits: Andrew Gene