Nestled in the heart of Seki Japan, Mcusta has been a part of Japan’s renown knifemaking industry since 1964. Often compared to Solingen, Germany, Seki is a knife-nut’s dream. Rich in resources such as iron sand, charcoal and water, Seki has been the center of Japanese cutlery production for over 780 years.

Buy the Mcusta MC-1 at BladeHQ

The odd thing is, when most American knife enthusiasts hear about Seki-City, Spyderco is often the first company to come to mind. Indeed, Spyderco has recently been producing some beautiful knives in Seki City, but their roots are 100% American. On the other hand, Mcusta’s roots run deep into the Seki-City soil, and the company has only recently arrived on to US market.

Today for your consideration is the Mcusta MC-1 series knife. This is actually their “Basic Series” folder although what you get is anything but basic. For those seeking a gentleman’s folder or a high end EDC option I highly recommend the MC-1. There are some interesting nuances that differentiate this knife from the typical “American Style” folder. Follow along as I share with you what I like so much about these simple Japanese blades.

General Dimensions and Blade Details

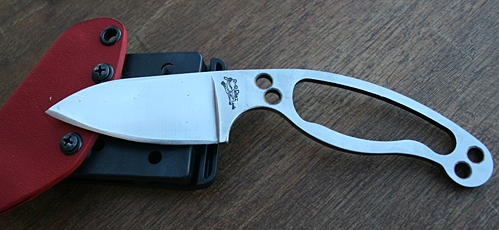

The MC-1 has a 4.25″ handle, a 3.25″ blade, an overall length of 7.5″ and a weight of 3.4 ounces. To me these are almost ideal proportions perfect for EDC, and the knife is large enough to potentially be used as an emergency tactical knife (not recommended, but it’s better than nothing). The MC-1 features a plain edge drop point blade with a fine tip and a flat grind starting 3/4 of the way up the blade. This blade, like all of the metal components in Mcusta knives, is laser cut for a precision fit.

For blade material Mcusta gives you the option of solid VG-10 or the handsome laminated damascus and VG-10 option shown above. This laminated knife is actually a core of VG-10 sandwiched in between 2 pieces of 33 layer nickle damascus and heat-treated to a Rockwell hardness of 59-60. This results in a visually stunning blade that is also very functional. As far as the steel goes, I love VG-10, it’s a very tough steel that can get wicked sharp and has excellent edge retention. Some find it a bit of a chore to sharpen, but I have never had a problem unless I let the knife get way too dull.

Handle, Ergonomics and Pocket Clip

Mcusta offers a wide range of handle scale materials including micarta, Corian (an interesting option) and a variety of exotic hardwoods. The knife featured in this review has African Ebony scales and the photograph below shows some of the other options. These scales are fitted over more laser cut steel and are hand finished. The simple pillar construction is a clean look that allows for easy maintenance. The knife is bolted together so if you wanted to, you could take it completely apart for a full cleaning. I’ve noticed that the liners aren’t milled out, but at 3.4 ounces the weight of this knife is still more than acceptable to me.

As far as ergonomics are concerned the handles feature some deep finger grooves for comfort and control. These grooves provide good grip in both forward and reverse holds. One thing to notice is the distinct lack of jimping on the thumb ramp (to dismay of some I am sure). In fact, there isn’t much of a thumb ramp at all. For a classier knife, I don’t think you really need it, but Mcusta does make some other models with these features (I’ll be reviewing a tactical version soon) if you want something with a little more utility.

Pocket clips are almost always a source of issues and the MC-1 is no exception. The good news is that this clip is both sturdy and elegant. Also, the clip is positioned at the very top of the handle so the knife practically disappears into a pocket. The bad news is that the clip is absolutely not reversible and only accomidates tip down right pocket carry. Notches have been cut into the handle to accommodate this “low rider” clip so flipping it over for left pocket carry is simply not an option. This is disheartening for me and the other lefties out there, but thankfully Mcusta offers other knives with a reversible clip (better than nothing).

Deployment and Lockup

The MC-1’s blade is deployed with a flick of a thumb stud. Deployment is silky smooth thanks to a teflon washer system. Teflon is a departure from the phosphor bronze washers found in most high end knives, but the deployment is still incredibly fast. I haven’t heard of any issues (either short term or long) with these teflon washers. The blade is locked in place with a thick liner lock. This is a very solid liner lock that is capable of taking some abuse and there is zero play in the blade.

Mcusta MC-1 Review – Final Thoughts

One thing that needs to be commented on here is value. Depending on the materials you can pick buy a new MC-1 for as low as $90 and they top out at around $140. When you consider the materials and workmanship involved here this strikes me as an incredible value.

Also, I have to say that it’s been a while since I’ve been so moved by a knife. You really need to see one of these in person to understand where I am coming from. I’ll admit that I am a sucker for hardwood handles, but the simple design and beautiful craftsmanship really hits home with me.

Of course, the MC-1 isn’t without fault, and my main contention is the non-ambidextrous pocket clip. Others may like to see more jimping, milled liners and perhaps even phosphor bronze washers (I’m curious to see how the teflon washers will stand up to the test of time). I’ll concede that these are valid concerns however, lets not forget the purpose of this knife and also consider the potential differences in the Japanese knifemaking industry. My guess is that the physical disconnect between Mcusta and the American market is largely to blame.

In my Mcusta Tactility review I explore a knife that addresses some of my perceived issues with the MC-1.

I recommend purchasing the Mcusta MC-1 at BladeHQ or Amazon. BladeHQ has a great selection of Mcusta knives in general, and their customer service is bar none. Buying anything through any of the links on this site earns the site a small commission at absolutely zero additional cost to you. This is how I keep the site running. Thank you very much for any and all support.