This post contains affiliate links. We may get paid an affiliate commission if you buy something or take an action after clicking one of the links on this web page.

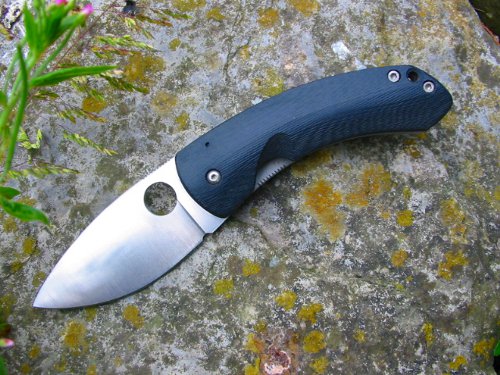

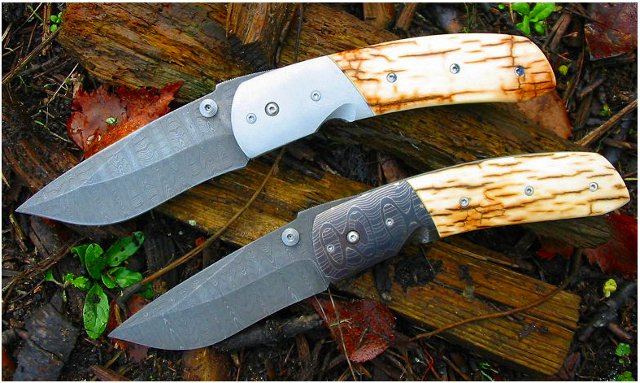

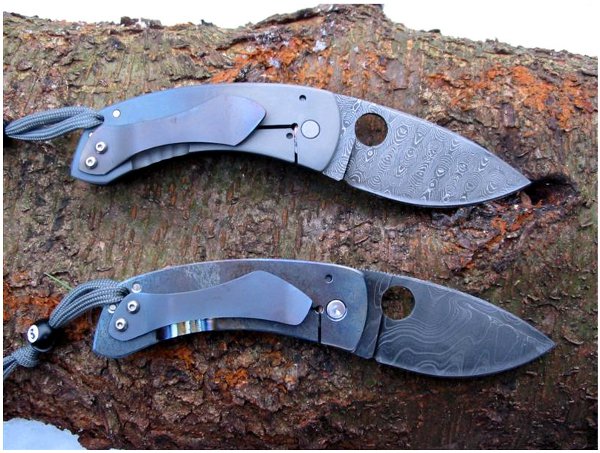

Filip de Leeuw is a Belgian knifemaker who makes some amazing folders. I came across his website, DeviantBlades.com and fell in love with his classically styled knives featuring modern materials and enhancements like pocket clips, thumb holes and titanium frame locks. His knives are clean, simple and meticulously finished. I find myself drawn to the elegant lines and find his knives a joy to behold.

Through emails I found Filip to be cordial, funny and extremely humble. I really enjoyed learning more about his work and I know you will too so lets get right to the interview.

Hey Filip, thanks so much for joining me. To start off, please tell us a little about yourself.

Well, I’m 33 years old and live in a small town near the city of Antwerp, Belgium. I live alone with my two dogs, both Spanish greyhounds. I spend my weekends and evenings working in my house (rebuilt almost everything about it) or in my workshop.

As for a day job, I’m responsible for evaluating the shooting permits. I’m one of those people who had the chance to turn his hobby into his job.

When did you decide to make knives? Why did you decide to make knives?

After graduating from university, I didn’t find a job right away. Wanted join the Police or Homeland security, but that didn’t work out. They weren’t recruiting people with my specific background at the time. So, I spent my days at home, looking for a job and doing some small jobs. At that time, I was living with my grandmother, because she couldn’t live alone anymore. One day, I was cleaning the shed in her garden and found my grandfathers old anvil and forge.

I was always interested in knives so when my dad suggested that I give it a try, I didn’t think twice. Of course, it didn’t work out like I had hoped. The metal just wouldn’t do what I wanted. A couple of days later, my dad found a book about knifemaking on the internet. We ordered it and I started making my first knife with a nice piece of precision ground RWL34. It worked out a lot better and I never really gave forging another try.

Do you have a “design philosophy”? If so, please tell us about it.

When I first started, I wanted to make ‘cool’ knives. The crazier they looked, the better I liked it. At that time, and with the help of the internet, I was in contact with some other knifemakers in Belgium. I noticed that most of the European makers had a very sober style; drop-point blade, standard wooden handle.

On the internet, I saw that the new makers used modern materials like G10 and Carbon fiber. I ordered some and used it to make freakishly looking knives that were totally unusable.

These days, my style really evolved, but it’s still pretty recognizable. My shapes look a lot more natural and I love it when the knife has flowing lines. I learned that the ‘basic’ blade shapes are still the most useful. No more extreme recurves for me!

Most of the time, I start a design with just some fluent lines on a piece of paper. With those few lines, I get in my shop and start cutting out a blade. More than often, I have no idea how it’s going to look like when finished. My ‘Freestyle’ model for example, is one of those knives that was never even sketched on paper. I found a piece of leftover steel in my shop with a shape that I really liked. I drilled a hole were I thought the pivot should be, and started working on it.

I know you license the “Spyderhole” from Spyderco (which is pretty cool in my opinion) and use it in some of your designs. How did Spyderco react to your designs? Were they supportive of your work?

I contacted Spyderco pretty early in my knifemaking career. On the net, I noticed that other folder-makers used the spyderhole with permission of the company. So I contacted them to ask what I should do. Peter H. Jhones, from Spyderco, let me know that I had to send some pics of my work to them and that they would decided if my work was up to their standards.

I replied that I was just starting out, and that my knives were still a ‘work in progress.’ They let me know that I could contact them whenever I felt it was the right time.

A couple of years later, I was ready. I sent Spyderco some pics and was given permission to use the opening hole. A milestone for me. You can call it a mental boost ! Off course my family and friends liked my knives, but well, you know, they kinda have to… When Spyderco said they liked them, I was really stoked !

Hah! Great story! Validation from one of the most respected knife companies has to be very satisfying.

I think it’s very interesting how you started out wanting to make folding knives – many knife makers start out with fixed blades and then “graduate” to folders as the moving parts and engineering involved is more complex.

How difficult was it to make your first folding knives? Do you have any background in metalworking, engineering etc?

I never learned anything about metalworking or engineering… sadly enough. I had to learn the hard way. When I was young, I always like making model cars, but that’s about it. I studied both Law and Criminology at the universities of Antwerp and Ghent.

Like everyone else, I started making fixed blades. But I never really liked fixed blades, because I can’t carry them in Belgium. So I wanted to build a folder. Problem was that I could find any parts in Belgium. It took me about 10 months to find some pivot pins. Titanium was impossible to get a hold of, so I couldn’t make a locking folder. (I read in a book that you needed titanium liners) So I started with a friction folder. (insane recurve and the ergonomics of a brick, but hey, it folded )

A German knife collector bought one of those early friction folders and talked me into trying a framelock version. At first, I was really hesitant, but he convinced me to give it a try.

So I ordered some titanium in the States, bought the Peter Atwood video about building framelocks and started.

At the different knife shows that I visited (SICAC Paris, Blade show Atlanta, Gembloux Belgium, Solingen Germany,…) I talked to my heroes about folder-making (Jens Anso, Matt Cucciarra, Alex Salsi…) and asked them how I could improve my folders. You have no idea how much I learned from those short talks.

I can only imagine what you gained from speaking with those modern masters – very cool.

I will say you also make some beautiful fixed blade knives as well. I see you have done it all from paring knives to swords. Do you have a preference between making fixed blades and folders?

I do all my work on a very small belt grinder at the moment. (2×20 inch belts, ½ HP) It’s really hard to make big blades on that machine. On top of that, there are not many folder makers in Belgium. Most guys specialize in neck knives and hunting knives.

I wanted to do something different. Nowadays, when you mention ‘the guy that makes framelocks’ in Belgium, most people know who you mean.

That’s why I prefer folders at the moment. The feeling that I get when I finish a framelock and everything ‘fits’ together, it’s just awesome.

I can only imagine, a well built frame lock is an amazing achievement.

That said, I love the simplicity of your friction folders and despite the undeniable popularity of your frame locks, the friction folders still seem to be very popular. Can you explain their background and appeal a little more?

At the Belgian knife shows, I used to be one of the few makers to use modern materials (g10, carbon fiber, titanium, gunkote, …) The younger visitors (18-25) really liked my style, but couldn’t afford to spend 200+ euro. A fixed blade is less expensive, but like I said before, it’s almost impossible to legally carry it in Belgium.

So I wanted to come up with a solution for them. I wanted to make a folding knife with good materials, modern looks, that was affordable. It also had to be legal to carry in most European countries. I thought about it for a while and came to the simple solution: a friction folder. I built a couple of them years earlier and even made a tutorial about it.

I cleaned up the old design, lost the horrible recurve, bought some cheap but good steel (A2) and some gunkote to prevent corrosion.

I made a couple of prototypes and they sold in a matter of minutes on British Blades Forum. The second batch didn’t last long either. I made a new tutorial about building friction folders that I posted on all the internet forum. This resulted in even more positive feedback.

I saw a video of one of your friction folders recently and it’s a fantastic design. I can definitely see why they are so popular!

What is in the future for Deviant Blades?

Well, there is a big project coming up that I can’t really talk about at this time. I’m sure you’re gonna love it.

There are also some slipjoints in the making. Got some new designs and I’m stoked to try them out.

Next to that, I really would like to try my hands at building a dual action folder, but I don’t have a clue yet how to start.

Some balisongs are also on the shortlist, but since they became illegal in Belgium, it’s not really that easy to build one. I have to visit a knifemaking friend in a more bali-friendly country and use his workshop.

The last two years, I haven’t really been able to have a constant production: I built a new workshop, got a new job with double the hours, and had some problems with my health. A lot of customers had to wait months (even more) to get some knives they ordered.

You have a lot on your plate! You will have to come back and tell me about that secret project, and hopefully you can reach a more stable point in your life so you can continue to make high your quality knives.

Alright, to wind things down, what is your current EDC knife?

Actually, it’s the same one for the last four years: A Dav Winch ‘Worker’ linerlock. I love that little blade. I carry it every day, clipped to my back pocket. On my belt, I carry a second knife in a leather sheath: my damasteel Tiny model.

I carried a Strider SNG for a while, but it was a little bit too big for my liking and it didn’t cut as well as the Worker and the Tiny.

Filip thanks so much for taking the time to do the interview. Is there anything else you would like to add?

I really want to thank you for this initiative and for giving me this opportunity!

Filip, the pleasure has been all mine. It’s been very interesting learning a little about you and your work.

If you want to see more about Filip’s beautiful knives, check out his website – DeviantBlades.com.

Hi there I can’t seem to find the proper website for his knives! I own a custom by him and need to contact him regarding warranty work, could you shoot me an email with his info possibly? Thanks in advance